|

Flax was one of the first European plants cultivated in America. From the earliest settlements, each ethnic group brought its own types of tools to process flax. The Germans, French, English, Swedes, Scots, all had tools in the style of their homelands. Their linen made clothing, bedding, towels, upholstery material, grain bags, wagon covers, sails and many other items.

Flax grows quickly, in less than three months. It is pulled out of the ground with the roots intact to preserve the full length of the fiber. Next, the seed was removed and saved for replanting. Surplus seed was pressed for its oil, which was used in paint and was burned in lamps for light. It was also the basis for printer's ink and had medicinal uses as well. Flax was the primary crop in colonial America.

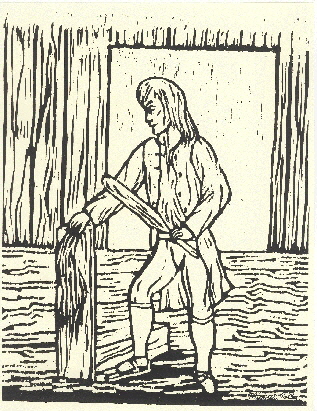

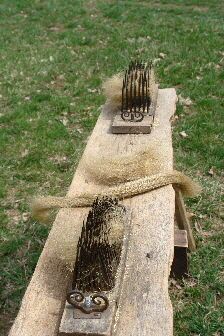

Processing the flax straw was a laborious process. After retting, the flax was broken, scutched or scraped, then combed; each step required its own unique tool.

|